— Product Design and Practice of Height-Adjustable Desks Based on Long-Term Reliability

As height-adjustable desks and standing desks gradually become standard configurations in offices and shared social spaces, market attention has long focused on functional specifications, visual differentiation, and short-term cost considerations.

However, in real-world applications, it is long-term stability, structural reliability, and delivery consistency that ultimately determine the true value of a sit-stand desk or electric standing desk.

Based on years of product R&D and project delivery experience, AOKE returns to the origin of R&D, re-examining the design logic, engineering pathways, and quality systems of height-adjustable desk products, and establishing a product development approach centered on long-term reliable use.

Common Challenges in Height-Adjustable Desk Products

Through long-term market research and customer feedback, we have identified recurring challenges commonly found in height-adjustable desk products across the industry:

- Structural stability gradually degrades under high-frequency lifting conditions

- Performance consistency between different production batches is difficult to maintain after mass production

- Gaps exist between theoretical specifications and real-world usage scenarios

- After-sales service and maintenance complexity are underestimated during early design stages

These issues are not caused by the failure of a single component, but rather are the result of system-level design and engineering strategies.

2.1Analysis of the Root Causes

From an engineering perspective, a height-adjustable desk is essentially a mechatronic system characterized by:

- Multiple load conditions

- Long lifecycle operation

- High sensitivity to structural rigidity and lifting synchronization accuracy

If product design remains limited to specifications alone—without integrated planning across structure, materials, manufacturing processes, and quality management systems—it becomes difficult to maintain stable performance throughout the product lifecycle.

Origin of R&D: Fundamental Assumptions in Product Design

At the early stage of product development, AOKE established the following fundamental assumptions:

- The core value of a height-adjustable desk lies in long-term stable use, rather than short-term performance indicators

- Stability must be achieved through engineering design and repeated refinement, not through end-user tolerance

- Product design must cover the entire lifecycle, including R&D, manufacturing, delivery, and after-sales support

Based on these assumptions, all design decisions are validated by returning to the origin of R&D.

Product Development System Based on Engineering Control

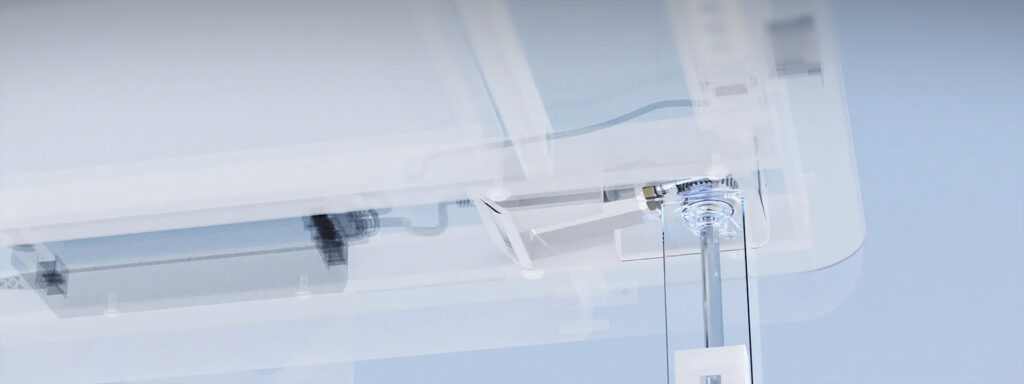

4.1 The Necessity of High-Level In-House Development

With over 90% of core structures and key components developed in-house, AOKE has established comprehensive engineering control across a wide range of height-adjustable desk application scenarios.

In-house development enables us to:

- Clearly define load paths and failure boundaries of critical structures

- Identify and mitigate risks during the design phase rather than relying on post-production correction

- Maintain a continuous R&D mindset focused on long-term performance optimization

In this context, in-house development is not a branding strategy, but an engineering prerequisite for long-term reliability.

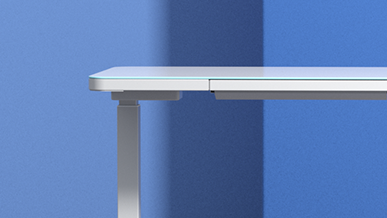

4.2 Structure-First Design Strategy

In the design of height-adjustable desk products, we prioritize:

- Non-linear changes in system stability throughout different lifting height ranges

- The impact of frame connection methods on overall rigidity and long-term fatigue performance, while maintaining aesthetic balance

All structural solutions must pass engineering analysis, prototype testing, and multiple validation cycles before entering the next development stage.

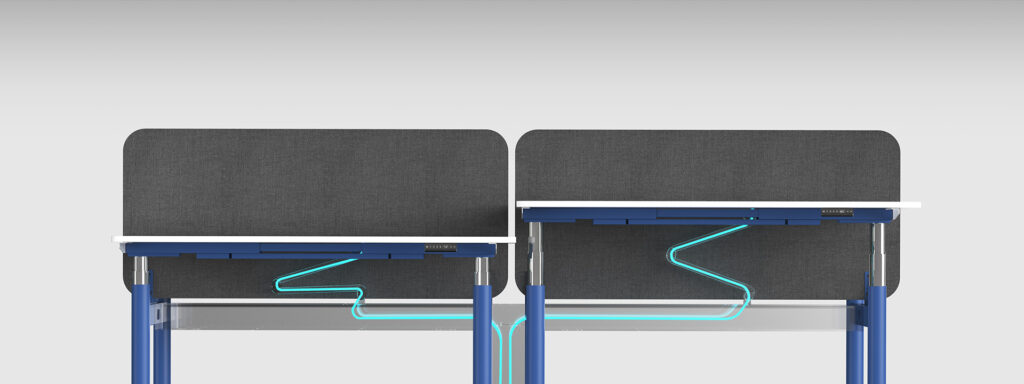

4.3Engineering-Oriented Quality Management System

To ensure that design intent is accurately executed in large-scale production, AOKE has established a full-process quality management system, including:

- End-to-end quality management (Man / Machine / Material / Method / Environment)

- Lifecycle durability testing and maximum load testing of critical structures

- Tiered validation mechanisms across prototyping, pilot production, and mass production stages

Within this system, quality is not a final outcome, but a continuously controlled engineering process.

Product Implementation and Practical Validation

Based on the above R&D and engineering systems, AOKE height-adjustable desk products demonstrate the following in real-world projects:

- Stable lifting performance under long-term, high-frequency use

- High consistency in performance output across customized standing desk projects and production batches

- Predictable and controllable quality during large-scale delivery

- After-sales and maintenance issues that are traceable, analyzable, and optimizable

These results confirm the practical feasibility of a R&D-driven, engineering-controlled product design approach.

Product Value from a Lifecycle Perspective

AOKE believes that product value should not be assessed solely at the point of delivery, but across the entire product lifecycle, including:

- Initial delivery quality

- Mid-term operational stability

- Long-term maintenance and upgrade costs

By returning to the origin of R&D and building a product development system centered on in-house development, structure-first design, and engineering-oriented quality management, AOKE is committed to delivering height-adjustable desk solutions that withstand long-term use and verification.

Why Do We Build Products This Way?

Because in long-term partnerships, stability and reliability always matter more than short-term specifications.